As a manufacturer of aftermarket spares, a question that we never fail to be asked is “when should I consider non-genuine spares?” Our standard response to that question is that when budget, lifecycle and purchasing restrictions allow, we always recommend that you buy genuine compressor and pump spares. An unexpected answer given our business, perhaps, but the answer is actually a little more complicated than it may seem.

Imagine a vessel that has been in service for 12 months. The starting air compressor may be due its first major service, whilst the bilge pumps are due a routine inspection. In nearly all circumstances, genuine spares from the original manufacturer are the only logical choice, primarily because they allow the manufacturer’s warranty to be preserved.

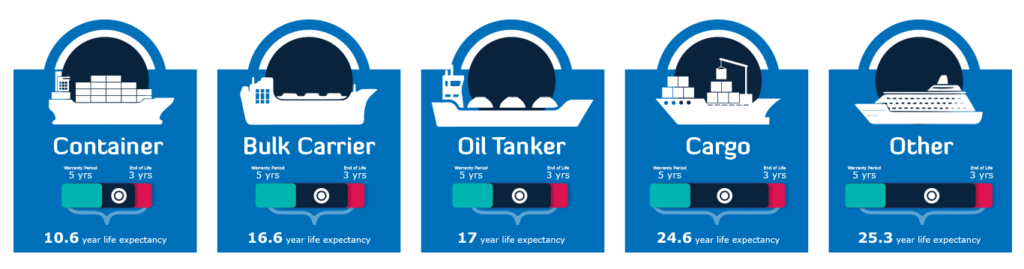

Now consider a container ship whose average lifespan is the shortest of the general use vessels at just 10.6 years. Once the on-board compressors are out of warranty (usually at the 5-year mark), should an engineer continue to specify genuine components for maintenance and overhaul? Such a vessel will be approaching its end of life, and considerations often turn to economic viability. Aftermarket spares provide a cost-effective alternative to maintain out of-warranty equipment whilst the vessel finishes out it’s service lifetime.

If you were to search for an answer to this question online, you would find countless articles discussing the subject. However, dig a little deeper and you will often find that they are sponsored content on behalf of, or published by the original manufacturers – Perhaps not the most impartial perspective. To offer a counter-point to this opinion, we’ve compiled a list of the top 6 reasons cited online why you should consider non-genuine spares.

Cost-effectiveness

OEM, non-genuine and alternative spares offer a cost-effective solution for maintaining and repairing marine pumps and compressors. By opting for these spares instead of Genuine parts, ship owners can significantly reduce maintenance expenses without compromising on performance or quality. Once the original manufacturers warranty has expired and the stipulation to exclusively use genuine spares has ended, aftermarket spares become the most economical option, often saving 75% of the cost of repair.

Availability

Aftermarket spares are often more freely available compared to Genuine parts, with shorter lead times for faster repairs. This is especially valuable for older or obsolete equipment where sourcing OEM parts can be challenging. The broader availability of aftermarket spares minimises downtime for customers/vessels, and helps to avoid mooring fines during unplanned repairs and maintenance.

Flexibility

Aftermarket spares suppliers have the freedom to choose from a broader range of suppliers and manufacturers, allowing them to select the most suitable option based on factors such as quality, pricing and delivery times. A perfect example of when this is critical is the recent Russia / Ukraine war. If the components for your equipment were manufactured in Russia, the sanctions are now such that these are no longer available from the same supplier. Since alternative spares can be sourced from multiple different manufacturers, the supply chain remains unaffected by comparison.

Traceability

Improved traceability is another interesting and positive aspect of non-genuine, alternative spares. By working closely with reliable factories, workshops and suppliers, the aftermarket can ensure that the origin and traceability are well-documented. Using batch numbers, parts are traceable the workshop/supplier, date of manufacture and material spec used. In fact, it’s possible to guarantee that the materials used, match or exceed the original parts.

Quality Control

The presence of non-genuine, alternative spares and parts in the market promotes healthy competition among suppliers. This competition encourages suppliers to focus on quality control, ensuring that the parts they provide meet or exceed OEM standards. As a result, we can access high-quality parts that deliver reliability and longevity, ultimately satisfying our customers’ needs. Thus, selecting reputable suppliers that adhere to recognised quality management systems and industry standards such ISO 9001 guarantees a quality component.

Life Expectancy

One interesting point that is often discussed is the life expectancy of non-genuine parts. Whilst original manufacturers will lead you to believe that aftermarket parts are not built to last, the opposite is usually true. Once common failure points have been recognised and evaluated, components are redesigned to be more suitable for the job at hand, often leading to a lower failure rate from the aftermarket than from the OEM themselves.

With all of this in mind, the next time a compressor or pump is in need of repair or maintenance, perhaps its time to consider an alternative to genuine spare parts.