Its widely accepted that marine air compressors, particularly starting air compressors, require strict maintenance schedules in order to perform at peak efficiency. We’ve compiled a list of some of the most commonly found problems, and their likely causes.

Lube Oil Pressure Low:

Ensuring proper lubrication is essential for the smooth operation of marine air compressors. Issues such as low oil pressure can stem from various sources, including:

- Faulty pressure gauge.

- Pressure gauge in closed position.

- Low oil level in the sump.

- Leakage in supply pipe.

- Suction filter is choked.

- Oil grade in the crank case is not compatible.

- Attached Lube oil gear pump is faulty.

- Worn out Bearing, clearance is more.

Abnormal noise during operation:

Unusual sounds during compressor operation can signify underlying mechanical issues. Identifying and addressing these issues promptly is crucial to prevent further damage:

- Loose foundation bolts.

- Worn out bearings, clearance is high.

- Imbalance crankshaft resulting in high-end play.

- Valve plate broken or faulty.

- Relief valve lifting below setting pressure.

- Bumping clearance is less.

- Piston worn-out, broken piston ring.

Excessive vibration:

Excessive vibration can indicate misalignment, worn-out components, or issues with the compressor’s foundation. Addressing these issues promptly is vital to prevent structural damage and ensure uninterupted operation:

- Foundation bolts are loose.

- Discharge pressure high, faulty discharge valve plates.

- Liner and piston worn out.

- Small bumping clearance.

Cooling water temperature high:

Proper cooling is essential to prevent overheating and maintain compressor efficiency. High cooling water temperatures can result from various factors, including blockages, pump failures, or insufficient water levels:

- Inlet or outlet valve for cooling water is closed.

- Inter-cooler is chocked.

- Cooling water in the expansion tank (if fitted) is low.

- Pipe passage becomes narrow due to scale formation.

- Water-pump belt or gear drive broken.

- Pump not working.

First stage discharge pressure high:

Fluctuations in discharge pressure can indicate issues with valves, pressure gauges, or mechanical components within the compressor stages. Addressing these issues promptly is crucial to maintain optimal performance:

- Pressure gauge is faulty.

- Inter-cooler air passage is chocked.

- 2nd stage suction valve is not closing, allowing air to escape from 2nd to 1st stage.

- Discharge valve of first stage is malfunctioning and remains in closed position.

- Spring of discharge valve is malfunctioning.

First stage discharge pressure low:

- Pressure gauge is faulty.

- Suction filter is choked.

- Unloader of first stage is leaking.

- First stage suction valve is not closing properly, resulting in compressed air leakage.

- First stage suction valve is not opening fully, leading to less intake of air.

- Discharge valve is faulty and remains open permanently.

- Relief valve after first stage is leaking.

- Piston ring of first stage is badly worn out, allowing air to pass.

Second stage discharge pressure high:

Similar to first-stage issues, abnormal discharge pressures in the second stage can stem from valve malfunctions, gauge inaccuracies, or mechanical wear and tear. Timely intervention is essential to prevent further damage.

- Faulty pressure gauge.

- Discharge valve to air bottle is shut.

- Second stage discharge valve plate worn out, and even the spring worn out.

- Valve is stuck in closed position.

- After cooler air passage choked.

- Air bottle is over pressurised.

Second stage discharge pressure low:

- Pressure gauge is faulty.

- Suction valve for second stage is malfunctioning, in open position.

- Suction valve for second stage is not opening fully, and thus less intake of air.

- Discharge valve is faulty and remains open during operation.

- Piston rings of second stage are worn out, leaking out compressed air.

- Relief valve of second stage is leaking.

- Un-loader of second stage is leaking.

First stage relief valve lifting:

Malfunctioning relief valves pose serious safety risks and can indicate issues such as faulty springs, blocked passages, or mechanical wear. Prompt inspection and replacement of faulty components are imperative to ensure compressor safety.

- Spring of relief valve is malfunctioning, thus lifting at less pressure.

- Discharge valve of first stage is not opening.

- Intercooler air passage is blocked.

- Suction valve of second stage is in stuck position.

- Water inside compression chamber due to a crack in the jacket and water leaking in.

Second stage relief valve lifting:

- Relief valve is malfunctioning, lifting at lower than setting pressure.

- Main discharge valve to the air bottle is closed.

- Discharge valve plates and spring are worn out, valve in closed position.

- Blockage in the after cooler air passage.

- Water inside the compression chamber due to crack jacket.

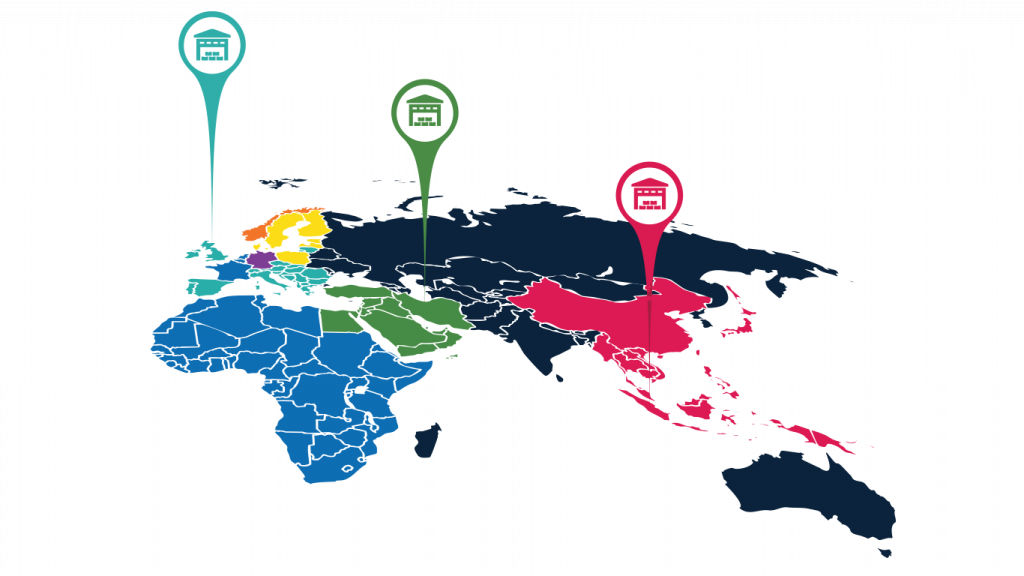

With MPCC’s engineering led manufacture and supply, we uphold a stringent 100% quality check standard across all components. Our unwavering confidence is evident through the inclusion of a no-quibble 12-month warranty. We are dedicated to providing maintenance spares that are not only cost-effective but also available worldwide, supported by our comprehensive engineering proficiency.

Thanks for listing out the common faults which would be very useful chart for the duty and maintenance staff. Very well laid out points and easy to understand.